LOW COST

FINE AND ULTRAFINE

METAL PARTICLES

Our products

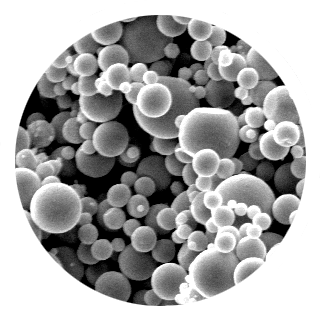

RMP metal powder is delivered as slurry, enabling easy and safe handling. The particles are spherical and RMP provides powders with different particle size distributions, from nanometers to 3 microns. RMP work with standard solvents for zinc and copper, but custom product with other solvents can be made on request. Samples are normally delivered with a concentration of 30-90 wt % of metal powder.

Please contact us at sales@reactivemp.com or tel. +47 402 80 843 for additional information, quotes, and request for samples.

About RMP

Reactive Metal Particles (RMP) is a Norwegian start-up company developing a new, low cost production process for fine and ultrafine metal particles. The founder, Eirik Ruud, observed the need for lower cost metal powders and invented the RMP process in 2009. He founded the company in 2010 to prove the production concept and industrialize the technology.

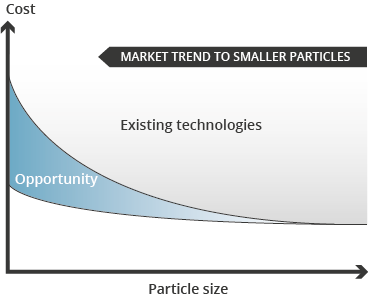

Metal powders are used in a range of industrial applications. Due to a strong cross-industrial miniaturization trend, the market is demanding powder with ever smaller particles. The emergence of nanotechnologies utilizing specific nano-material properties is also strengthening this demand. However, current production methods cannot supply particles in the low micron to nano range in a cost effective manner. RMP will close this market gap. The proprietary production technology is able to meet both necessary cost level and material properties required by the industry.

RMP currently has operational test reactors (kg/h) for both copper and zinc in place. A pilot for semi-commercial volumes (tons pr year) is now being planned. RMP’s technology is applicable for a range of metals. The company plan to do in-house production of selected powders and will license the technology for other metals and markets.

RMP is owned by managment and investors with a strong industrial track record. Scatec AS, the majority share holder, is a private incubator investing in and developing companies within clean tech and advanced materials. The company has over the last years brought several technology start-ups from the early stages to industrial scale.

The RMP technology

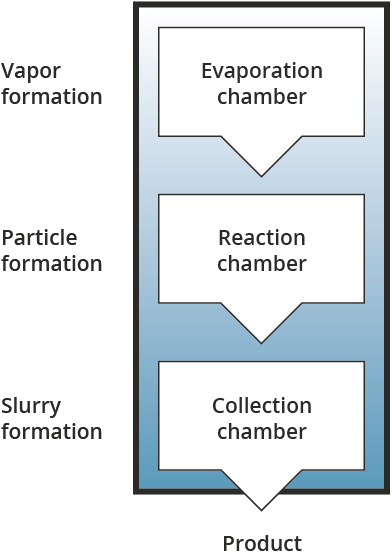

The RMP technology is based on inert gas condensation where a metal vapor is produced and subsequently mixed with an inert cooling gas – forming particles. The particles are separated from the cooling gas and mixed with a liquid forming a HSE-friendly, easy-to-handle slurry product.

Inert gas condensation is a well understood process, but conventional technology cannot meet material specifications in a cost-effective manner. The RMP innovation lies in the reactor design, meeting customer specifications at competitive cost. This patented solution enables a high production rate while maintaining necessary process control to tailor the particle size.

RMP has demonstrated production rates of many kilograms of powder per hour from a small test reactor. The technology is highly scalable and a pilot reactor are now being planned.

The company has developed a strong technology platform through activities on zinc particles and copper powder. Plans to develop the reactor for other metals (Ag, Al, Ni, Co) are in place, and there is potential for future development of a range of elements, alloys, bi-metals and coated particles.

RMP’s strategy is to develop metal powders in partnership with customers to ensure that the proper material specifications are defined and customer needs are met. If your company has specific metal powder requirements, please contact us for further discussions.

Applications and Projects

Electronics:

With its copper particles RMP is focusing on the electronics industry. We aim to supply the existing market for low micron and sub-micron copper particles in conductive pastes, inks, and fillers. Nano and sub-micron particles are also well suited for the emerging field of printed electronics.

Investigations on other potential applications for our copper powders are under development:

- Antibacterial

- Catalysis

- 3D-printing and MIM

- EMI shielding

Zinc-air batteries:

As a part of the Horizon 2020-funded project ZAS! RMP’s zinc powder will be tested as a new anode material in rechargeable zinc-air batteries. The work is done in partnership with leading institutes and companies in the battery industry. Read more about the project here.

Anti-corrosion coatings:

RMP ultrafine zinc powder has demonstrated improved performance in anti-corrosion coatings. Tests have been performed in partnership with leading industry players. Read more about the project here.

RMP is still in the early stages of exploring its technology’s potential and market opportunities. RMP’s combination of material properties and cost position will make both existing and emerging markets relevant. Future applications to investigate may be chemical reactants, additives to conventional powder metallurgy, and binders in tooling systems, pigments, and magnetic materials.

The RMP core team

Eirik Ruud

CEO and Founder

Eirik Ruud holds a MSc in Material Science from University of Oslo (UiO). He has demonstrated strong skills in both technology development and funding, proven through several rounds of private placements and developing the RMP technology to a pre-industrial stage.

Rita Glenne

CTO and Board Member

Dr. Glenne has a Ph.D. from the Technical University of Trondheim (NTNU) in Material Science. She has extensive experience in developing technology into processes and products. Dr. Glenne previously worked at SINTEF, Norsk Hydro ASA, REC ASA and as Vice President of Technology at REC Solar AS.

Fredrik Nilsen

Process Manager

Fredrik Nilsen holds a MSc in Material Chemistry from the University of Oslo. He started in RMP at the beginning of 2014, first as a part time employee and later in a full time position.

John Andersen Jr.

Chairman of the board

CEO of Scatec AS, a privately held industrial investor focusing primarily on high-technology, early-phase companies within material science and renewable energy. Prior to joining Scatec, Mr. Andersen served 12 years with Renewable Energy Corporation ASA (REC), for the last six years as Group COO

Ole Grimsrud

Board member

VP of Research and development, Scatec AS

Dr. Ralf Schmidt

Board member

CEO i Biovotec AS. Dr. Schmidt has extensive experience in R&D and production, and has held COO/CTO positions in several high tech companies.

Jørgen Dale

Board member

VP Business Development, Scatec AS